Where Heritage Meets Innovation

With innovation rooted in ethics and a legacy built on movement, KD Knit is uniquely positioned to help brands lead the next era of luxury – where material excellence and environmental responsibility are inseparable.

Founded at the intersection of movement and material, KD Knit Corp. has been a pioneer in creating elegant, functional apparel for dancers and athletes for over 40 years. Born in the heart of New York City’s performing arts community, our designs have been worn by professional dancers, yoga practitioners and A-list celebrities alike – each drawn to our signature fusion of comfort, beauty and performance.

From the beginning, we’ve held a deep belief that clothing should do more than clothe – it should empower movement, elevate the everyday and reflect the values of those who wear it. Today, that belief lives on in our evolution from a premium apparel company to a fiber-innovation leader.

We are proud of our commitment to transparency, employee well-being and environmental stewardship. We donate annually to causes that reflect our core values.

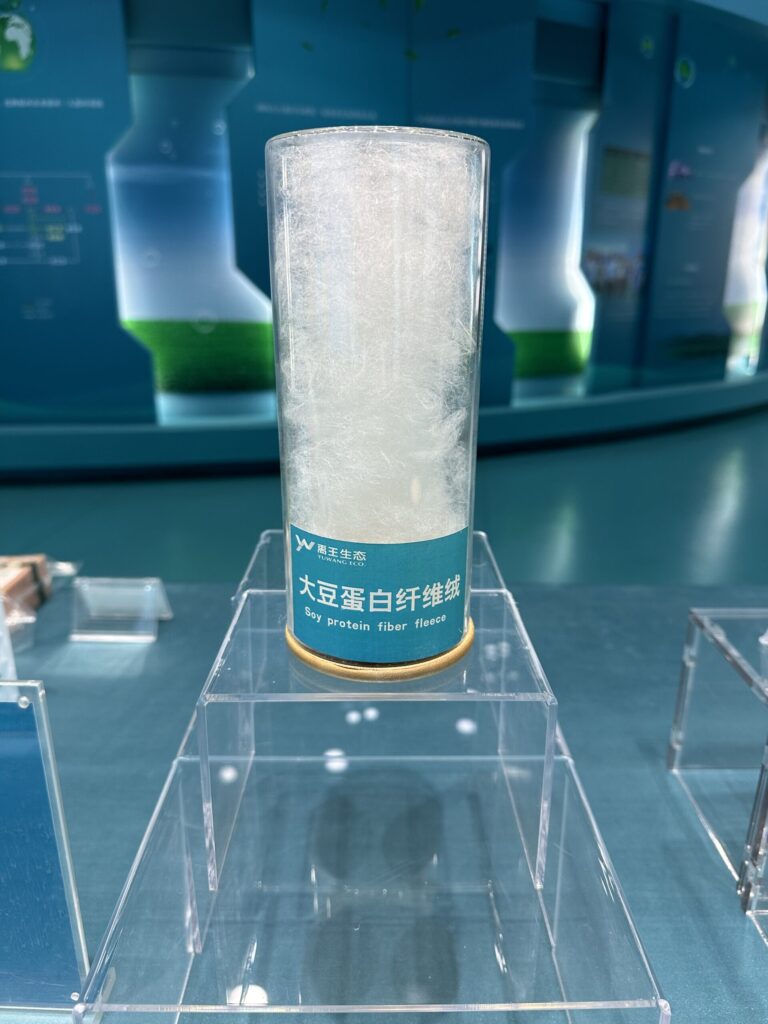

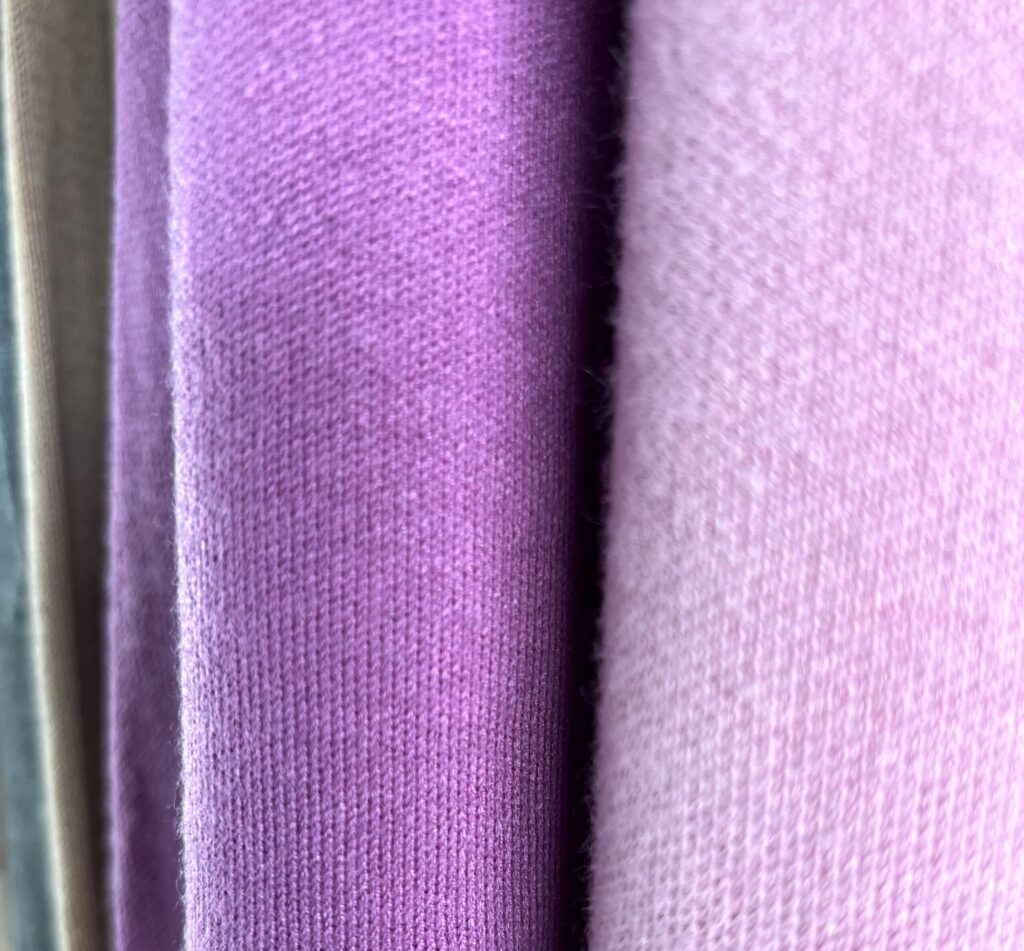

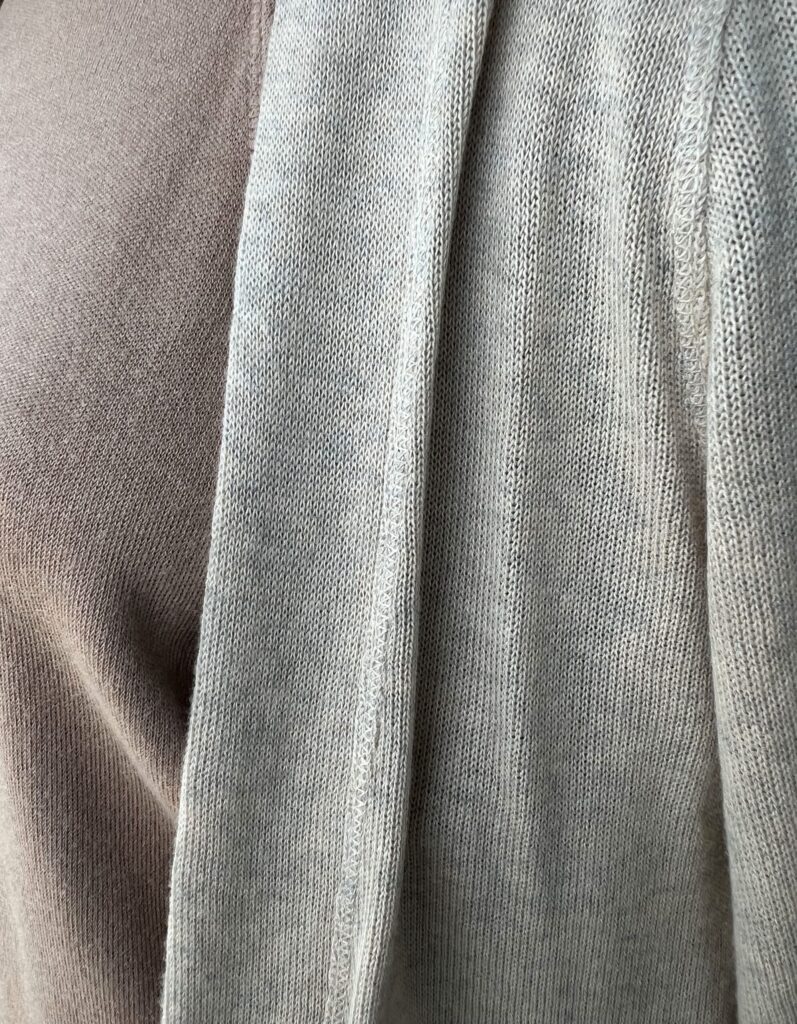

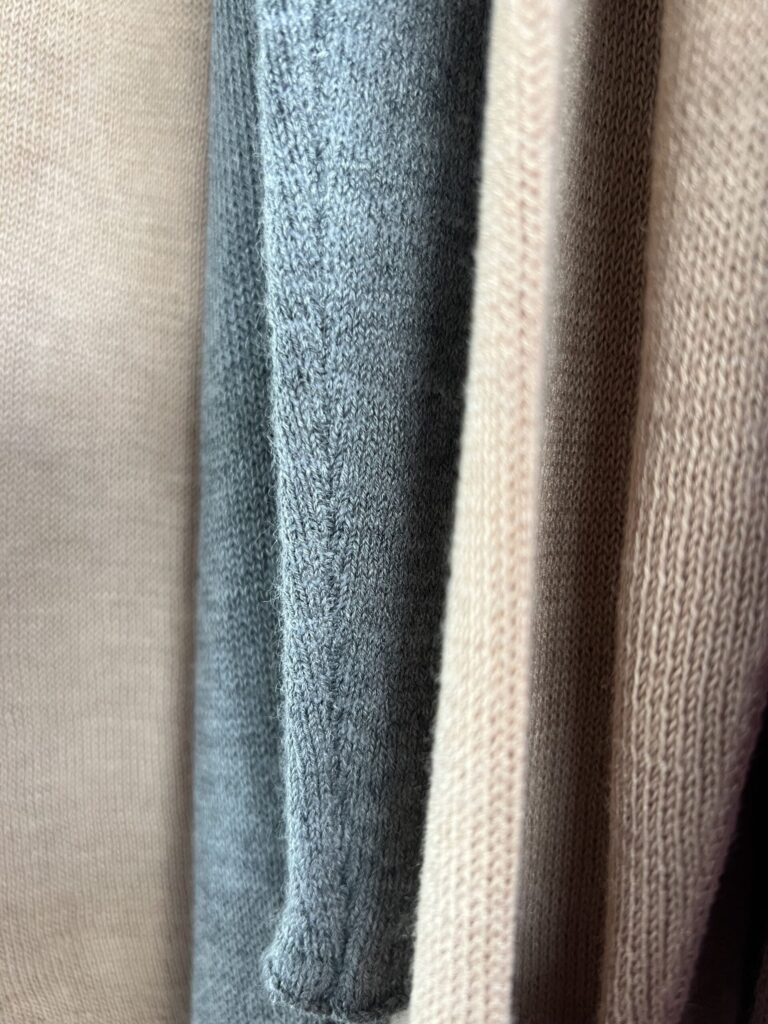

At the heart of our current chapter is Vegetable Cashmere® – a regenerative, soy-based fiber designed to meet the demands of modern luxury: elegance, wellness, performance and sustainability. By transforming a byproduct of soybean oil production into a soft, durable and luxurious fiber, we are demonstrating what’s possible when design meets conscience.

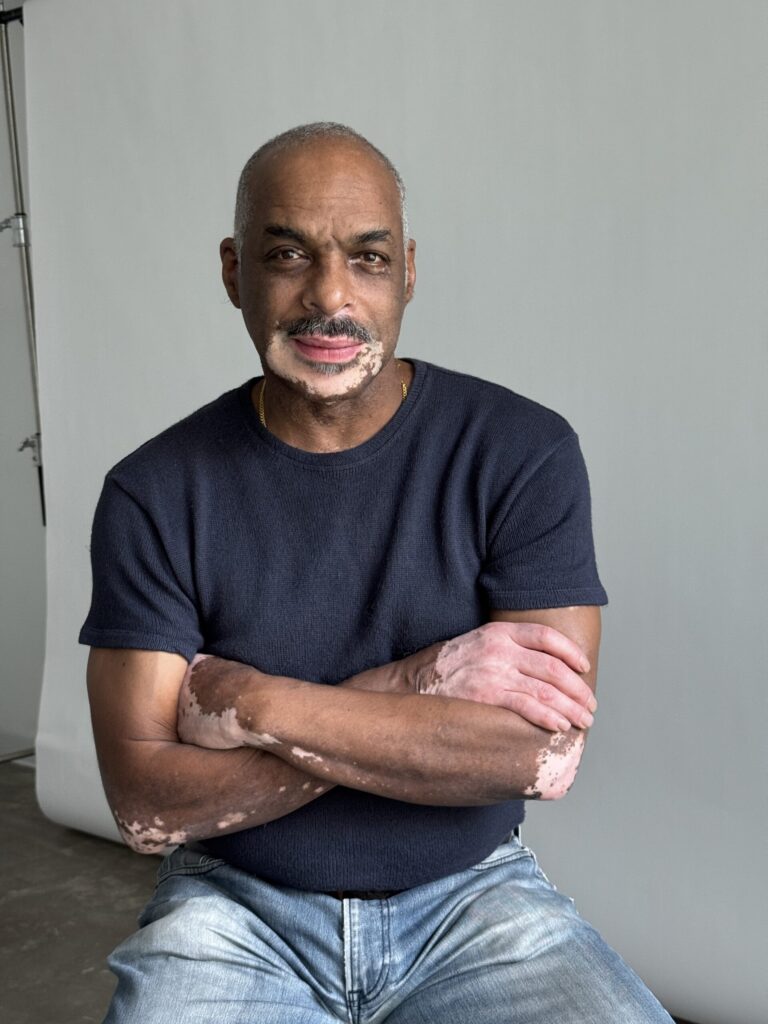

David Lee

KD Knit Corp. is led by founder and CEO David Lee, a former professional dancer turned entrepreneur, whose creative vision and technical expertise have fueled the brand’s expansion into sustainable materials.

After a celebrated career as a dancer with the Oakland Ballet Company and Alonzo King LINES Ballet, David transitioned from the stage to the studio, co-founding KD Knit in 1980. He studied knitting technology at Stoll in Germany and Shima Seiki in Japan, and holds a degree from American University in Washington, D.C. Over the past four decades, he has designed and manufactured knits for both the KD brand and numerous private labels, blending artistry with technical mastery.

Today, David’s deep understanding of performance, material innovation and sustainability continues to guide KD Knit’s evolution as textile innovator.